5. Initial instrument operation

Completing all front and back panel connections, the following procedures need for initial use to connect Electrochemical Analyzer or potentiostats

1. Push rear panel power switch to the ON (“|”) position.

2. Tighten motor shaft assembly onto stainless steel cell holder.

3. Remove the electrode by holding the screw and turning the

electrode body counterclockwise.

4. Polish the electrode by following the instructions in the

Polishing Kit (PK-3 kit). See Chapter 7 for more information.

5. Replace the electrode (See chapter 7). Note that a slight

upward pressure must be applied to the electrode body to start the

threads. When the electrode is replaced with another working

electrode, the power switch should be turn "OFF".

6. Place a test solution in the cell vial. A common test solution

is 1 mM potassium ferricyanide in 1 M KCl.

7. Place the reference and counter electrodes inside two holes of

the teflon holder and attach the cell leads. Start purging the

solution with inert gas as described previously. For this initial

experiment, purging 5-10 minutes will be adequate. Please regulate

gas pressure carefully.

8. If the RDE is being used with the potentiostats, the control

of the rotation rate is able to control manually from the front

panel or remotely via TTL CONTROL using the potentiostats software.

9. The instrument is ready to use. Now the electrode will begin

to spin when the RUN command is initiated in the software.

10. After the experimental run, the motor shaft assembly can be

raised and the electrodes can be rinsed or polished as needed. The

system is then ready for the next experiment.

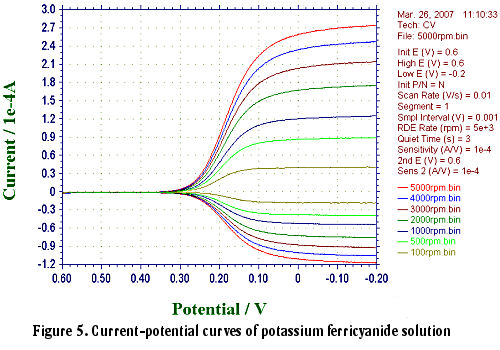

Typical test parameters are:

Working electrode : 4 mm Platinum electrode

Reference electrode: Ag/AgCl

Counter electrode : Platinum wire

Test solution : 0.5 mM Ferricyanide/1 M KCl

Initial voltage : +500 mV

Final voltage : 0 mV

Scan Rate (Volt) : 10 mV/S

Rotation Rate : 100 to 5,000 rpm

Sensitivity : 10-5

|